Automate Your Manufacturing Company

Manu Online - The cloud ERP for small and mid-sized manufacturers that focuses on flexibility and high levels of business process automation.

Transform Your Manufacturing Business with Manu Online

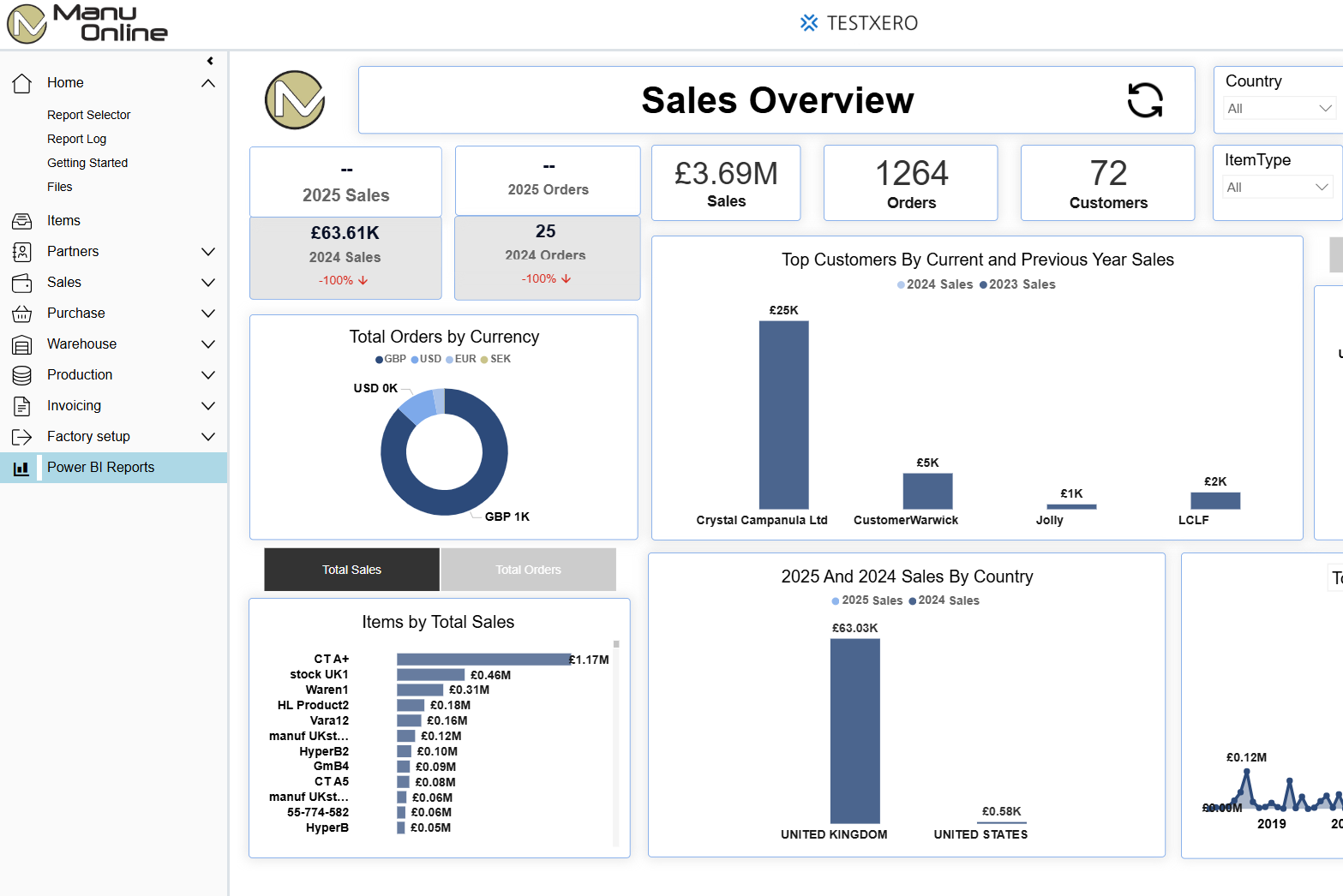

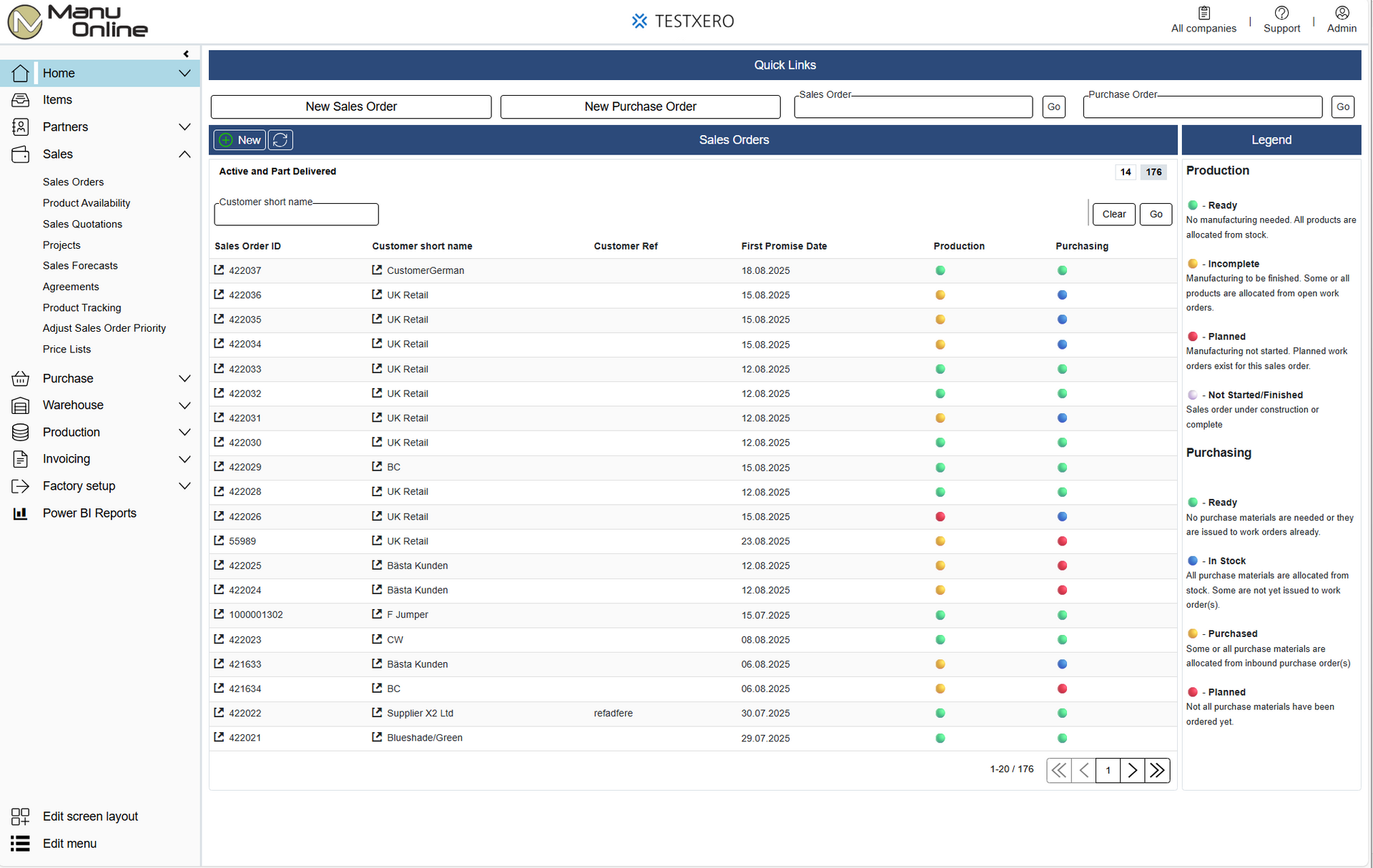

Use it for materials and work control, order handling, planning, invoicing etc. Often called an "MRP system", but Manu Online is much wider than just MRP.

Our system is designed from the ground up for manufacturing companies. Controls, and automatically plans, all of your operations whether you are in a small single factory-start up or a high volume multinational organisation.

We know manufacturing.

Are you here?

Running your

manufacturing business with an accounts system and

lots

of spreadsheets?

Struggling

with a legacy system that can’t get the

benefits

of a modern ERPs?

Failing to efficiently deal with company growth?

And want to get to here?

Running your

manufacturing business in

realtime

with

efficiency,

functionality

and

transparency

- Accurate Order Book

- Accurate Inventory

- Accurate Procurement

- Traceability

- Accurate Costing

- Realtime

- Scaleable

Why

Manu Online?

Grows

Productivity

If your company is missing promised delivery dates to customers, or carrying to much inventory or just generally working chaotically, then implementing a good ERP system will massively pay back.

Perhaps more importantly than money, managers and owners will sleep much better at night. You’re worth it.

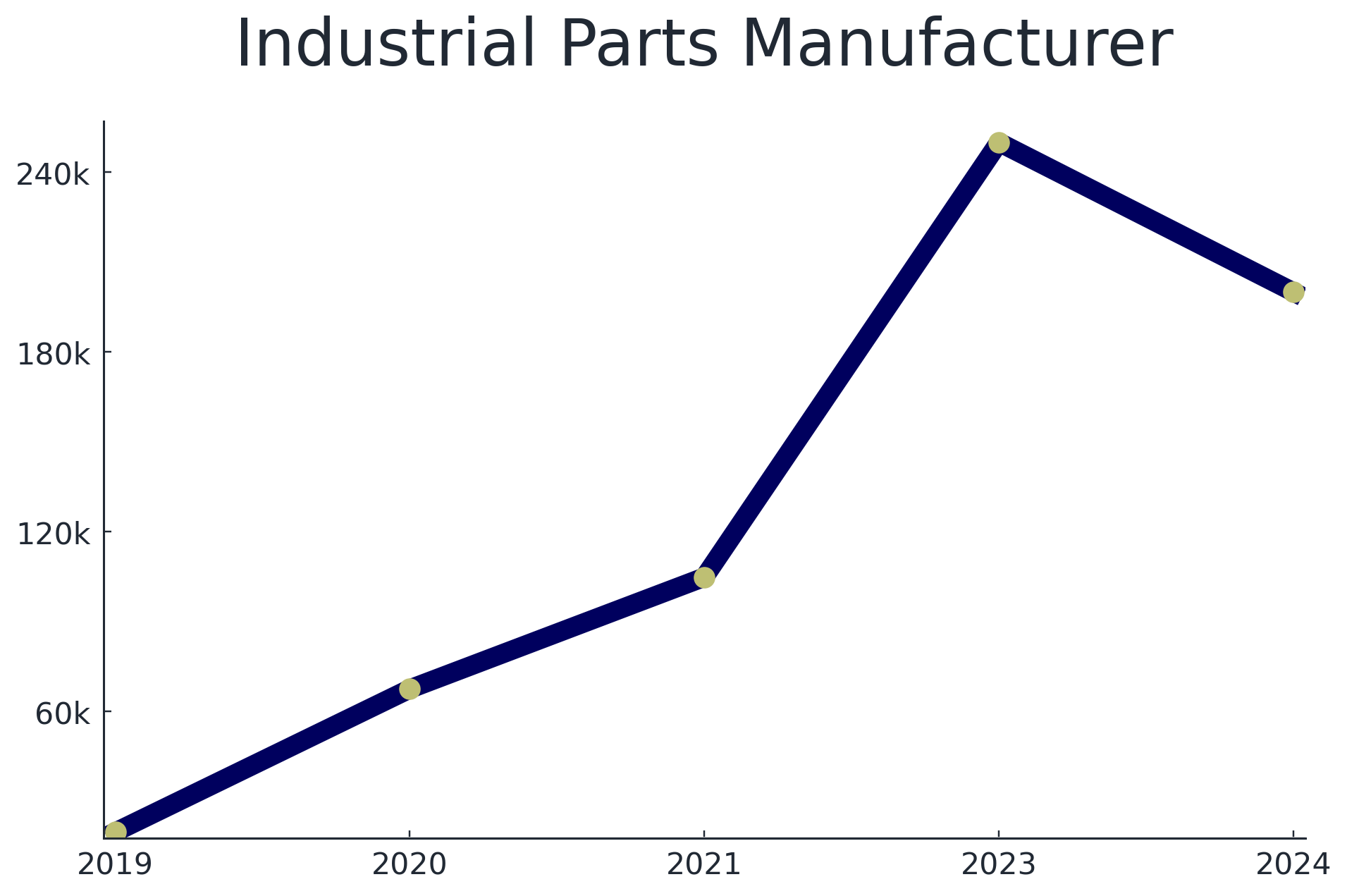

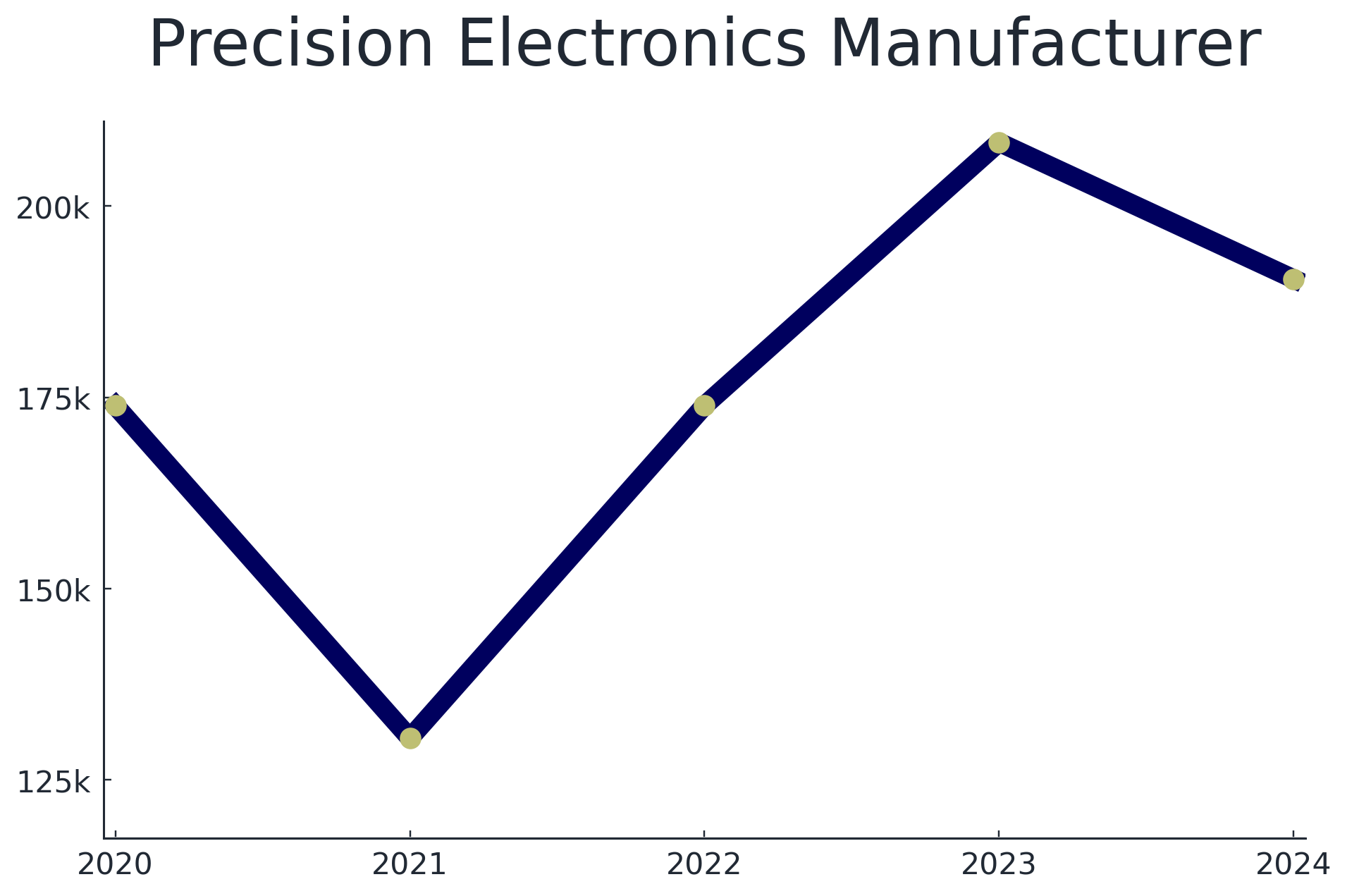

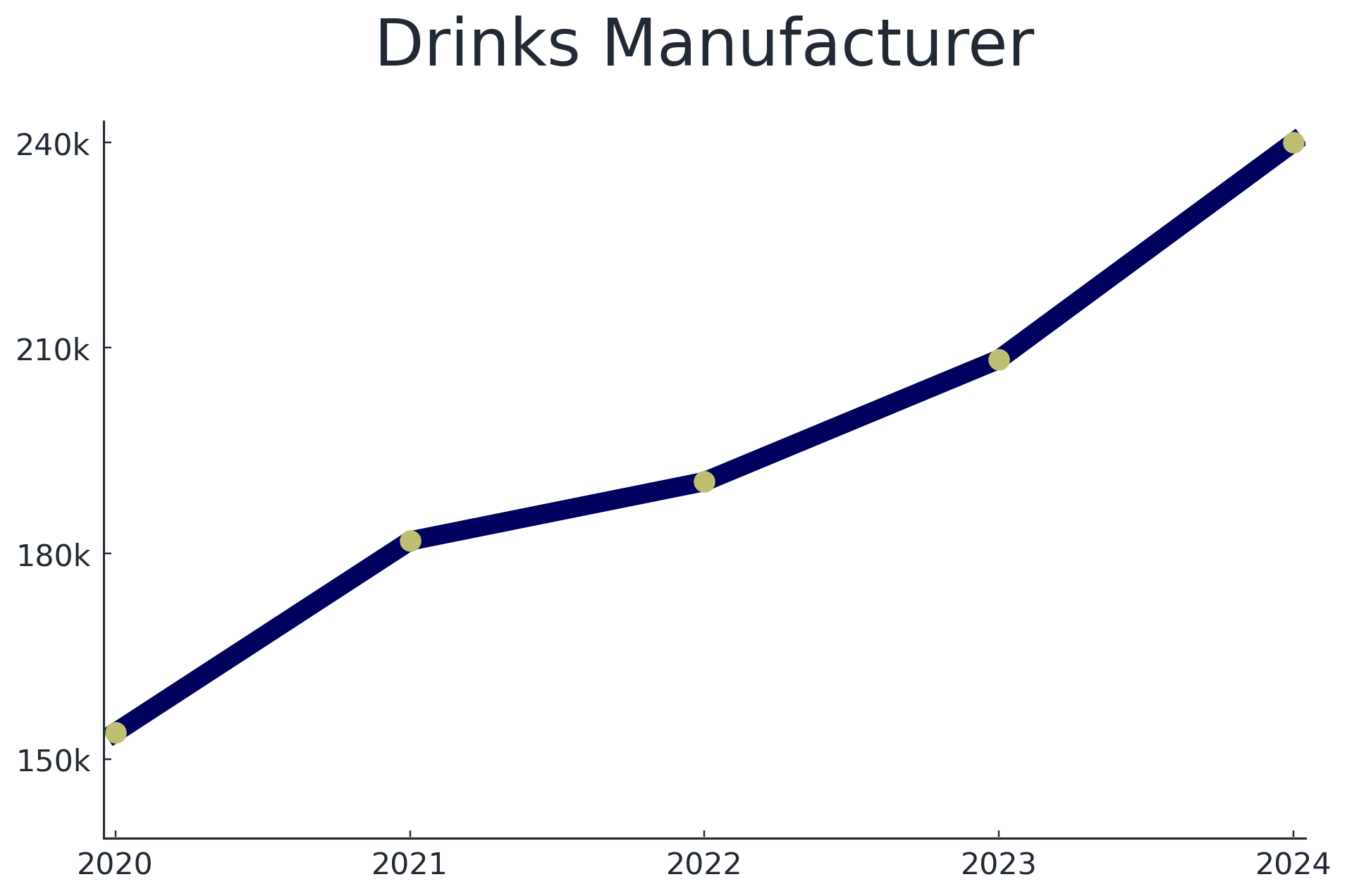

Sales per Employee

(Real public data from Manu Online customers)

Multiple

Editions

If you’re a small company with big plans, you can start small and grow big. Manu Online has three “Editions” to help you scale. Upscale at the click of a button. Don't fear growth.

Options &

Extensibility

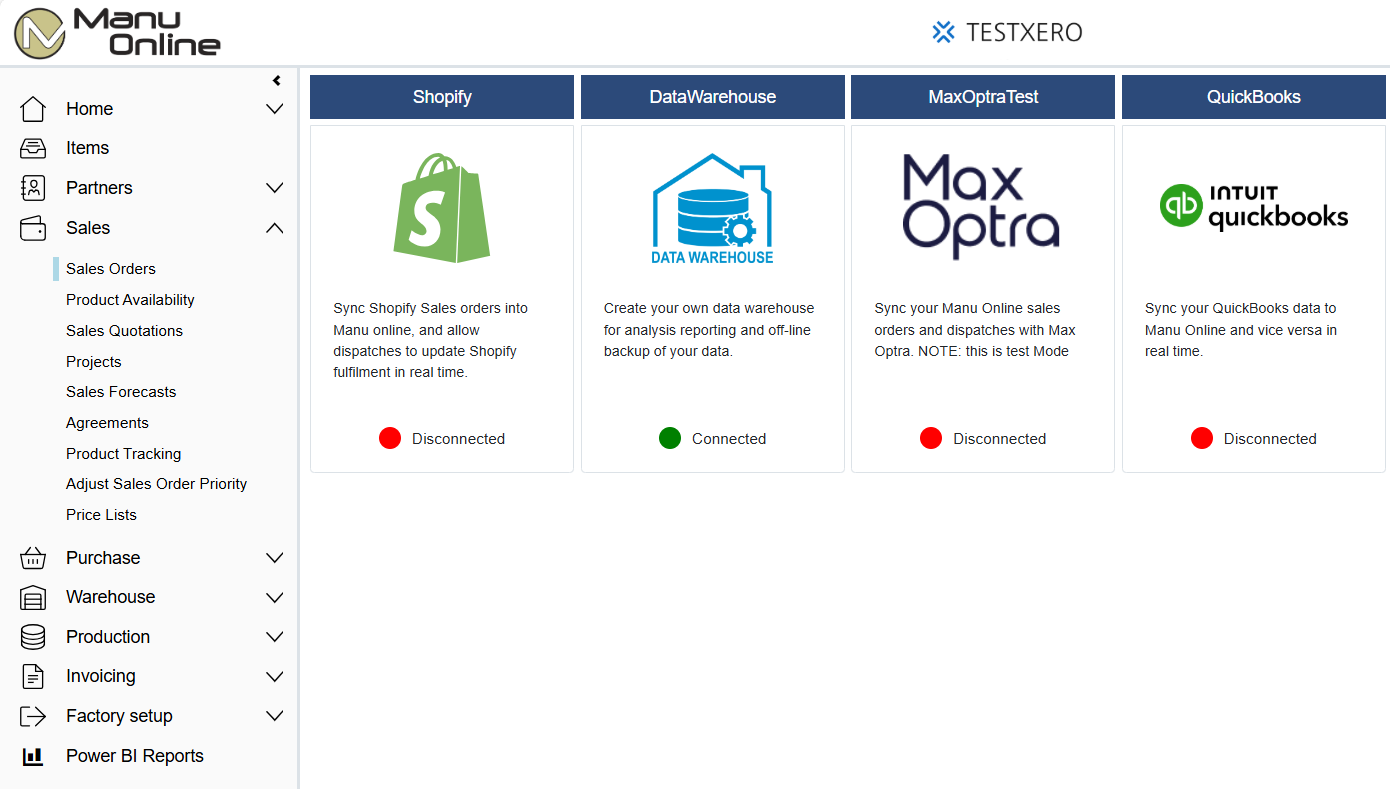

Manu Online is extendable.

In our Enterprise Edition you can add menu items to screens of other applications. Data you have collected to your own servers can be linked back into Manu Online.

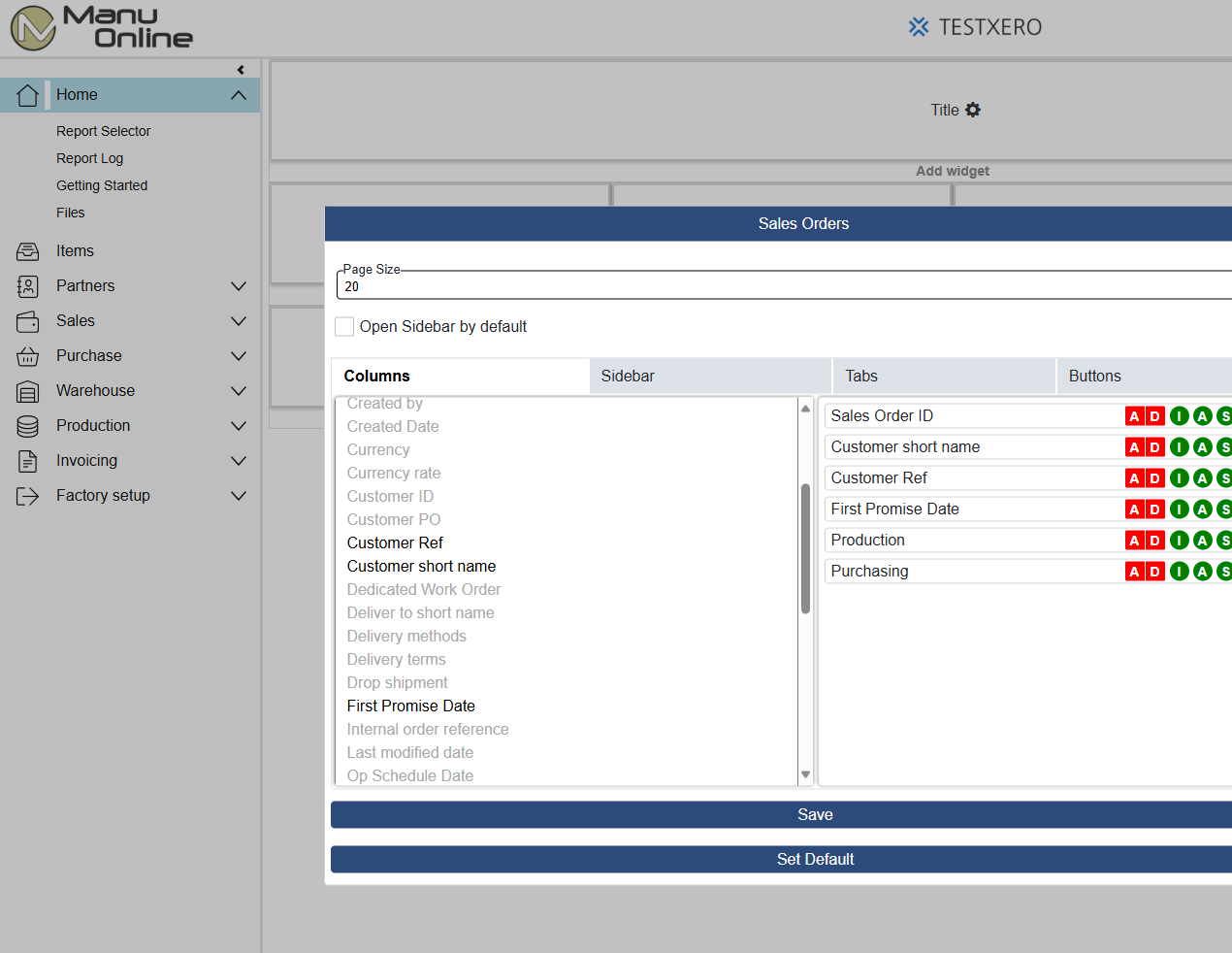

Flexible environment

Manu Online is flexible.

In our Portal, you can configure user screens to show the data that you want to see. With the Enterprise Edition you can do this for whole teams.

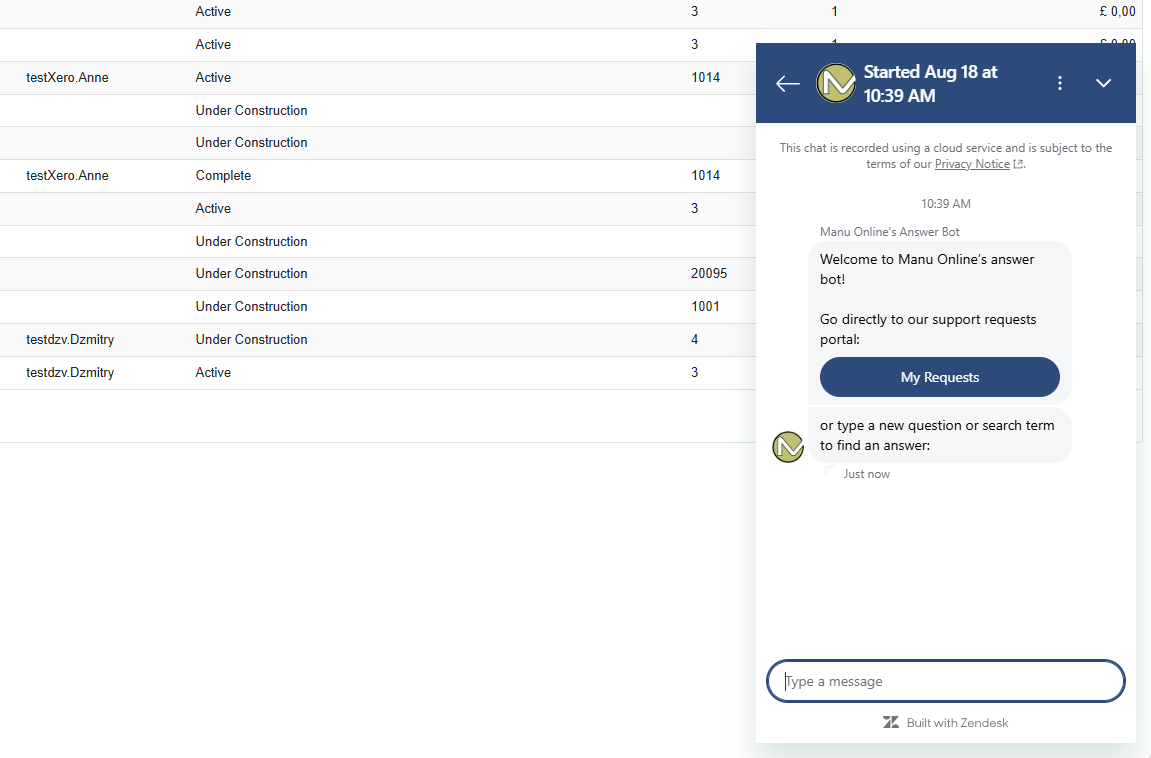

Support &

Service

We help you with this stuff.

We have a built in ticketing system for support. And we provide online professional services for consultancy, data manipulation etc.

What’s next?

Talk to us about your manufacturing.

We will evaluate your situation and find the best way forward for you. And if our system is not suitable for your processes we will also tell you that, as our business is based on long term relationships, not a quick software sale.

After that, we can open you a no-commitment free trial for evaluation and prototyping with your own data.

Whether the implementation phase is challenging or very easy, our Professional Services team is here to help, so that you get a powerful and functioning system that will take your business to the next level.